Jeanette Lee tried The Sleeve, at the 2016 West Coast Challenge. Her use of the Sleeve, and her comments about it, were unsolicited. Billiard Engineering’s vendor booth was next to her challenge table.

“I like it! It’s pretty cool.” – Jeanette Lee

To thank Jeanette for all she does for the sport, Billiard Engineering will donate 10% of the purchase price of each Sleeve to the Black Widow Foundation to support its Junior Camp Program. We believe there is no better way to support the sport of billiards than by providing mentors to our young billiard players. Many of the Pro players participate in the mentoring program and we want to help. Read more about the Black Widow Foundation here.

Throughout the history of pool & billiards there has always been the problem of the cue stick sticking to the players bridge hand when attempting a shot. This is caused by a number of things including hand perspiration, skin oils, relative humidity, cue stick and hand contamination, etc. This problem induces inconsistencies in the player’s stroke and is a distraction from concentration on the shot. The problem has been around in Europe since cue sports were originally invented in the 15th century. It has existed in North America since billiards came to the English colonies.

Until now, remedies have been limited to:

1) Application of hand chalk or powder.

2) Frequent hand washing and cue stick wiping.

3) Wearing a glove on the bridge hand.

Most every pool player will utilize one or more of these remedies and each remedy presents with its own disadvantages. Hand chalk or powder is messy and difficult to remove from the pool table’s playing surface and in many establishments chalk is no longer provided. Frequent hand washing is time consuming and requires that the hand and cue stick be allowed to dry completely in order to obtain a smooth sliding hand & cue stick interface. With a glove, it too can get contaminated, is often taken on & off during play.

Billiard Engineering, by sleeving the cue stick, has resolved the pool cue sticktion problem with The Sleeve. Our product not only accomplishes the functions afforded by wearing a glove, but, also eliminates its disadvantages, eliminates the need to wash hands frequently to remove skin oil and contaminants and eliminates the use of messy friction reducing chalk or powder. Most importantly, The Sleeve ensures a consistent interface between the hand and the cue stick which provides consistency in each shot.

Hardwoods are by their very nature porous. Players can apply a sealant to the shaft to prevent pore entry of contaminants. While a sealant will aid in preventing chalk and other contaminants from entering the pores and discoloring the cue, they can create more sticktion.

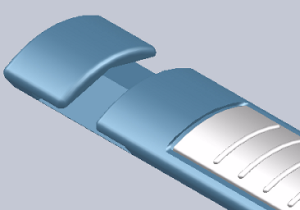

Billiard Engineering’s design, development effort, and functional testing for the Sleeve, were orchestrated to minimize the hand/cue sticktion problem. Additionally, the effort was intended to improve consistency between each stroke without damage to the cue stick. These efforts have resulted in the configuration shown in Figure 1.

Figure 1 – The Sleeve

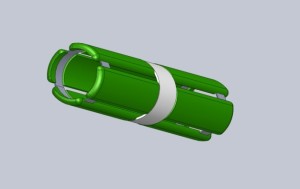

The Sleeve consists of 5 identically shaped injection molded plastic slats that wrap around the tapered pool cue longitudinally. The slats are shaped to accept, hold, and retain a silicone band that allows the device to expand and contract. Since the band will not fall out of the slat, the band holds the 5 slats of the Sleeve together even when removed from the cue stick. See Figure 2.

Figure 2 – Slat End View

The substrate of the Sleeve has been selected based on both manufacturability and the results of over 590 separate coefficient of friction tests. It is molded with polytetrafluoroethylene (PTFE or TeflonTM) filled plastic which provides a smooth and consistent pool cue stroke. Since the Sleeve cannot be molded with pure PTFE, PTFE filled plastic has the lowest frictional coefficients possible which supports movement on the cue with the least amount of effort. The band is sized to exert no compression on the shaft at the ferrule which provides exceptionally low force for movement between the Sleeve and the cue stick.

The over mold is molded immediately after the substrate and prior to ejection of the slat from the injection mold. This second material or over mold is a Thermo Plastic Elastomer (TPE) which is attached in the same way the colored grip is attached on a tooth brush. The TPE has a soft feel and high frictional coefficient against the skin which makes the Sleeve easy to hold even with an open bridged hand.

The configuration accommodates the tapered shaft by permitting the five segments to separate as the cue diameter increases. The elastic band pulls the slats back together as the sleeve is slid to a decreasing diameter.

Critical to the product’s success is the material selection for the designs. If you have ever slid a cardboard box across the floor, you noticed that it is harder to start the box sliding than it is to keep the box sliding. This is because there are two frictional coefficients at work. The first is the static coefficient of friction (CoF) and the latter the dynamic CoF. While some publications list a material’s CoF properties, the actual CoF is dependent on the two materials in which the CoF is measured.

Having a product with very low static and dynamic CoF will allow the sleeve to slide over the cue with very good function, improved consistency and an enjoyable feel. Accordingly, several materials (with and without additives, as well as with and without cue stick sealants) were tested to determine their static and dynamic CoF on test boards of finely sanded maple in order to identify appropriate initial material choices. While there remains some static and dynamic friction between the device and the cue stick, both are at their minimum. The static CoF remains much more consistent between each cue stroke and the dynamic CoF is exceptionally low.

B&C has considered two very different sleeve configurations and a total of six different designs. The first configuration consisted of fabric and included two designs; one of a tubular elastic fabric design and the other a quilted wrap around.

The second sleeve configuration utilized injection molded components and included four separate designs. All six different designs were evaluated for form, fit, function and user interface. Four separate designs were chosen for modification and further development. These included three thermoplastic injection molded designs and an elastic fabric design. The molded designs were first prototyped via 3D printing using SLA technology.

Figure 3 – Four Slat Sleeve

The slat configuration was prototyped using both a four and five slat configuration (Figure 3). The 5 slat was chosen over the 4 slat as the 5 slat design reduced the extent of cue stick exposure between the slats when the device expanded.

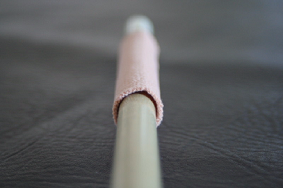

Figure 4 – Elastic Fabric Sleeve

Billiard Engineering initially considered a fabric and realized that any sewn configuration would produce a seam that would be just as distracting as a dent in the cue stick. Another option was a knitted design.

Several knitted prototype configurations were produced and tested. One is depicted in Figure 4. One knitted configuration held it’s shape better than the others when slid on the shaft without folding or bunching up. When we applied dyes to the fabric we noticed an increase in frictional coefficients. Additionally, we had concerns during the fabric design process that a fabric configuration could have an unsubstantial and/or flimsy presentation to the consumer. For these and other reasons, we discontinued the fabric sleeve concept.